Ways to Improve Rack Airflow Management

Rack Airflow Management serves as the second part of the 4Rs of Airflow Management and outlines a strategy for applying best practices in Data Centre airflow management. The strategy was developed by Upsite Technologies a leading supplier of Airflow Management Solutions.

The core principle of best practices in airflow management is to prevent the mixing of hot and cold air-streams. CRAC units supply cold air to the cold aisle through floor grilles to cool the IT equipment. Meanwhile, the hot exhaust air from the IT equipment exits the rack through the rear door and flows into the hot aisle.

However, this is not always the case.

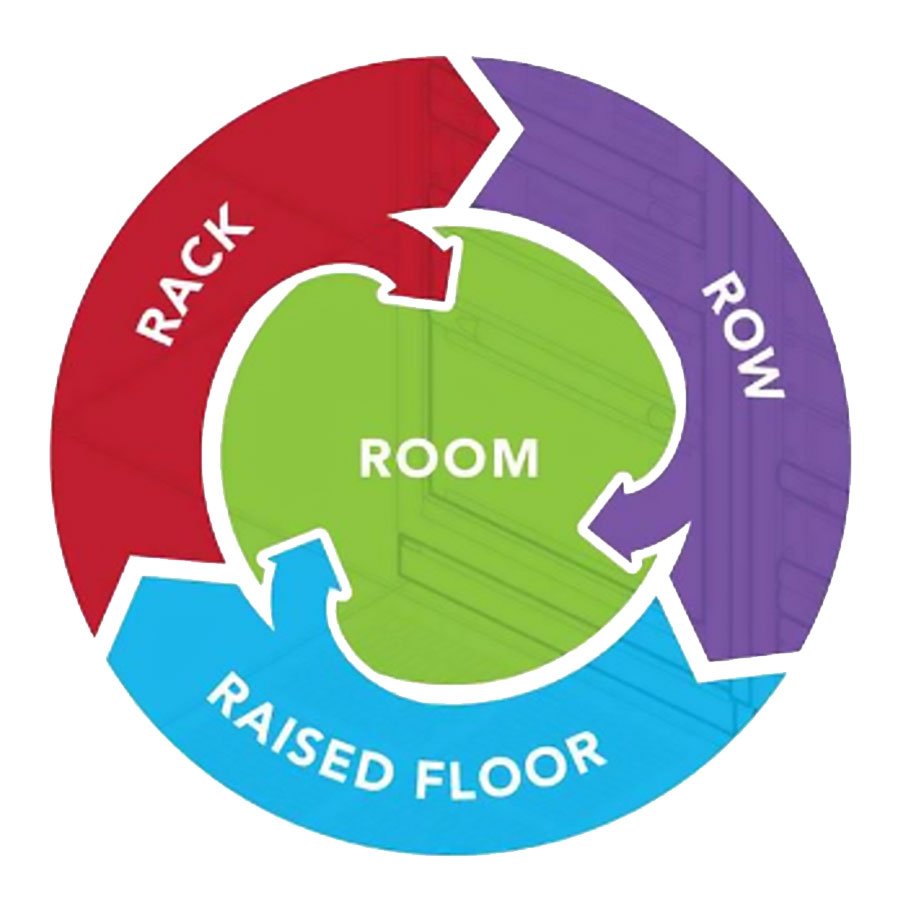

What are the 4Rs of Airflow Management

The 4Rs break down airflow management into four distinct levels. Firstly, Raised Floor Airflow Management requires proper placement of floor grilles, sealing cable openings with floor grommets, and using underfloor air baffles to restrict air to the necessary areas. The second part focuses on Rack Airflow Management, and the third part addresses Row Airflow Management. The final level is the Room, where you can optimise cooling systems by raising temperature set-points and adjusting fan speeds.

This can result in switching off unnecessary cooling units and achieving energy efficiency gains.

Steps to Improve Rack Airflow Management

Rack Airflow Management aims to prevent air streams from mixing around the rack face or from gaps under or between racks.

In racks with poor airflow management, hot exhaust air from IT equipment or the hot aisle can circulate back to the front of the racks. When this occurs, it can mix with cold air, causing latent cooling and hot spots or allowing the air to return through air intakes, which raises equipment temperatures. To prevent this, sealing all the areas where hot air can migrate is essential.

- Blanking Panels – Seal unused rack space within the rack mounting area using blanking panels.

- Air Barriers – Use air barriers to seal gaps between the sides of racks and the mounting area, as well as to seal gaps under racks on castors or leveling feet, and small gaps between racks.

- Infill Panels – To address larger gaps between racks, using infill panels provides the solution. Missing racks or building support structures often cause these gaps.

- Network Switch Cooling – Network switches often breathe hot exhaust air due to their positioning in Data Centre racks. A network switch duct can resolve this issue.

Blanking Panels

Blanking panels seal the gaps between pieces of equipment within the mounting frame area. Traditionally, installers used metal plates as blanking panels that required fixings for installation. This process was time consuming, as a result was sometimes overlooked.

EDP distributes blanking panels from HotLok and EziBlank that provide a better solution.

Both products feature a tool-less design that allows for quick and easy installation. HotLok blanking panels are available in 1U or 2U sizes and include integral finger guards that simplify both installation and removal.They also feature cantilevered sealing vanes that create a touch-tight fit to installed equipment or other panels, which eliminates gaps. EziBlank blanking panels consist of 6U sheets that are scored at 1U intervals. This scoring allows users to easily resize them to the required amount by snapping them at the desired point. Users then simply clip the panels in. The design allows operators to blank out entire racks within a few minutes.

Air Barriers

You can utilise rack air barriers to seal other gaps within or around the rack. Firstly, gaps can exist between the sides of the rack and the mounting frame within racks. Even if you use blanking panels, these gaps can still allow hot exhaust air to circulate back to the front. You can use air barriers such as RackSeal foam tape or HotLok RAM Kit to seal these gaps. Secondly, you can seal gaps under racks or small gaps between racks with RackSeal. Alternatively, you can use AisleLok Under Rack Gap Panels to seal gaps under racks.

Infill Panels

Sometimes rows of cabinets can have larger gaps needing a different solution to prevent hot air circulation. These gaps can occur where racks have been moved or because of building support columns. In such cases, you can position Infill Panels to seal these larger gaps. EDP provides solutions from AisleLok and EziBlank. The AisleLok Adjustable Rack Gap Panel attaches to the side of a rack using magnets. You can then extend the pull-out panel and attach it to the next rack. Panels are available to seal gaps up to 1,524mm (60”). EziBlank Wall is a triangular structure where each side is a different popular rack width. You can rotate the structure to the desired width and position it between the racks to seal the gap. Most adopters of this solution find a typical payback within two weeks, although some Data Centres have experienced payback within 24 hours!

Network Switch Cooling

Operators typically install network switches at the top and rear of a 19” server cabinet. Many switches have air intakes at the side or rear. As a result, they breathe hot exhaust air. This can lead to switches overheating, resulting in network downtime or even complete failure of the switch. Sometimes you deliberately leave gaps in the front of the rack to allow cooling in, but this just allows hot exhaust air to mix with the cold air. A better solution for network switch cooling is to use a ducting sleeve that allows cool air in without mixing with the hot air. HotLok Switchfix is a range of ducts designed to work with specific network switches, while EDP SwitchDuct is a steel unit into which you install the switch. The unit can house up to three 1U network switches.

By applying these strategies at the rack level and following other best practices, you can optimise cooling at the room level. To find out about airflow management solutions or to discuss a requirement, please contact us.