AisleLok Aisle Containment – The easy way to improve Row Airflow Management

AisleLok Aisle Containment is a unique aisle containment system that uses Rack Top Baffles and either Bi-directional Swing or Sliding Doors, that can be self-installed straight out-of-the-box and start delivering improvements in Row airflow management and efficiency.

We conclude Airflow Management Awareness Month and our recent series of blog articles by looking at the improvements that can be made at the rack Row level. Our first blog article, ‘Improving Raised Floor Airflow Management Helps Optimise Data Centre Cooling’, looked at the changes that can be made to improve airflow management at the Raised Floor level. Next, we looked at the improvements that could be made at Rack level in our blog ‘Improve Data Centre Rack Airflow to Help Optimise Cooling’.

As with Raised Floor and Rack levels, the aim of good airflow management at Row level is to prevent the mixing of air streams between the cold air cooling the IT equipment and the hot exhaust air expelled by it. The best way to do this is through the installation of an aisle containment system.

Aisle Containment is an established and effective means of improving airflow management within Data Centres and IT rooms. It involves segregating the hot and cold aisles and in doing so it greatly improves the management of both conditioned air delivery and hot air return paths. Aisle containment solutions reduce the risk of hot and cold air mixing, bypass airflow, and air re-circulation – all of which contributes to cooling optimisation & potential energy efficiency gains at the CRAC unit.

There are two types of aisle containment systems:

- Cold Aisle Containment – Where the cold aisle is enclosed via a roof and end of aisle doors. It is then flooded with conditioned air that cools the equipment. As the aisle is enclosed the hot exhaust air is unable to wrap over the top or around the sides of the cabinets and mix with the cold air.

- Hot Aisle Containment – This is where the hot aisle is contained and hot exhaust air is directed into the ceiling plenum where it returns to the CRAC units cooling the Data Centre.

Both methods have their Pros and Cons, but essentially deliver similar results. Aisle Containment systems normally need to be designed and expertly installed which can be a costly process, particularly where the need to add additional racks to rows is a requirement.

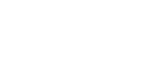

AisleLok Modular Aisle Containment

AisleLok is the Data Centre industry’s first out-of-the-box modular aisle containment system that can be easily self-installed, and start delivering the benefits of an aisle containment system in minutes. Its flexibility allows the system to be easily modified as Data Centre requirement change.

The AisleLok aisle containment system consists of three primary components: Rack Top Baffles, End of Aisle Doors and Rack Gap Panels.

Rack Top Baffles come in two configurations; Angled for Cold Aisle Containment applications and Vertical for Hot Aisle Containment. The baffles are available in a number of sizes to suit different cabinet widths including standard 600mm and 800mm designs. Installation is easy; simply attach the supporting ‘legs’ to the panels and then place on top the server cabinets. The baffles are completely tool-less with the panels attaching through the use of magnets. Angled panels are positioned at the front of the racks, while the vertical attach at the rear of the rack. The angled baffles do not fully enclose the aisle but still deliver the benefits of aisle containment by preventing hot exhaust air from wrapping over the top of the racks.

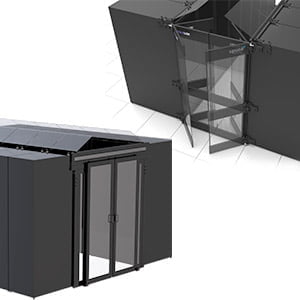

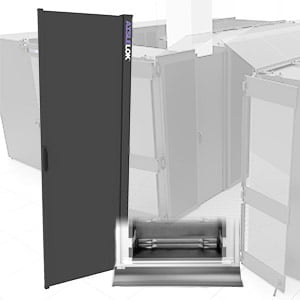

End of Aisle Doors attach to the sides of the cabinets at the end of rack rows, or to the purposed designed fixing post for aisles with only one row of racks. There are two types of doors: Sliding Doors that are self-closing, or Bi-directional Swing doors. Again, these are available in a range of sizes to support cabinets from 42U to 50U.

Rack Gap Panels complete the solution. Under Rack Gap Panels are used when racks are on castors or levelling feet and prevent air passing underneath the racks. While Adjustable Rack Gap Infill panels fill in the gaps created by missing sever racks or gaps caused by obstacles such as building support columns. These attach to the cabinet sides through the use of magnets.

Each component will deliver an improvement to the airflow management within the row, but for the biggest improvements they should be used in conjunction with each other. After installation, the cooling system at room level can be adjusted to optimise the cooling. It is this optimisation that leads to energy efficiency gains and reduces energy costs.

If you would like more information on how to improve data centre row airflow management, or have issues optimising cooling that you would like assistance with, please contact us and a member of our team will be happy to help.